Choosing the right sewing machine for leather work

Sewing machine for leather is built to handle the specific demands of leatherwork. This might be a heavy-duty domestic machine or a specialized industrial machine.

Difference between a standard sewing machine and a sewing machine for leather

| Power and Durability | Needle and Thread | Feed Dogs and Presser Foot | |

| Leather Sewing Machines | Often have stronger motors and more robust construction and built to handle the stress of thicker materials | Typically use heavy-duty needles designed to penetrate thick leather and strong, waxed threads like bonded nylon or polyester. | Have stronger feed dogs and adjustable presser feet to handle the thickness and stiffness of leather. |

| Regular Sewing Machines | May struggle with thicker materials or continuous use. | Standard needles and threads may not be suitable for leather, especially thicker varieties. | Standard feed dogs and presser feet may not be as effective with leather. |

TYPES OF LEATHER SEWING MACHINES

1. Domestic Sewing Machines:

- Heavy-Duty Domestic Machines

Heavy-Duty Standard Domestic Sewing Machines are usually used to handle thicker materials like leather. They often feature strong motors and sturdy construction.

Janome HD3000 Heavy Duty Mechanical Sewing Machine

Beginner-friendly mechanical sewing machine with 18 stitches, free arm, jam-proof bobbin, built-in needle threader, and heavy-duty metal frame. Includes a hard cover and instructional guide.

SINGER 4432 Heavy Duty Extra-High Sewing Speed Sewing Machine

Heavy-duty sewing machine with 110 stitch applications, 1-step buttonhole, 1100 spm speed, reverse stitch, LED light, drop feed, adjustable presser foot pressure, and included accessories. 1 Durable metal frame.

Singer 4411 Lifestyle Heavy Duty Sewing Machine

Heavy-duty sewing machine with 69 stitches, 1100 spm speed, 50% more power for tough fabrics, durable metal frame, top drop-in bobbin, and included accessories.

Singer Heavy Duty 6700C Sewing Machine

Heavy-duty computerized sewing machine with 411 stitches, 7 buttonhole styles, 1 font, 1100 spm speed, adjustable presser foot pressure, drop feed, LED light, and LCD screen.

2. Industrial Sewing Machines:

- Cylider Arm Machines

- Flatbed Machines

- Post bed machines

Industrial Sewing Machines are made especially to handle thick materials like lather and are intended for heavy-duty, continuous use. Compared to domestic machines, they are more powerful, durable, and accurate.

For More Serious Leatherwork:

| Cylinder Arm Machines | Flatbed Machines | Post bed machines | |

| Ideal for | Curved or cylindrical objects like bags, pouches, and sleeves. | Flat items like belts, wallets, and leather garments. | Heavy-duty sewing tasks, including thick leather and multiple layers. |

| Key Features | A cylindrical arm that allows for easy sewing around curves. | A flat bed surface for stable sewing. | A strong, sturdy frame and powerful motor. |

| Benefits | Increased maneuverability and precision, especially for intricate designs. | Easier to set up and operate, particularly for beginners. | High-speed sewing, durability, and precision. |

Cylinder arm machines

Perfect for bags, pouches, and other leather items because of their cylindrical arm, that makes stitching curved or cylindrical shapes simple. This machines come in various sizes, from small benchtop models to large industrials ones.

A compound feed system, which is usually built in cylinder arm machines, guarantees even fabric feed, which is crucial for thick materials like leather.

Flatbed Machines

Ideal for stitching flat items like wallets, belts, and leather clothing because of their flat bed surface. They come in variable sizes, from small home machines to large industrial ones.

What’s more they can be equipped with a variety of presser feet, including walking feet, binder feet, and edge stitching feet.

Post bed machines

Often have a roller foot, which is perfect for sewing close to the edge of the material and for sewing stitching delicate curves and shapes. They usually come with a number of accessories, such as a binder attachment or a zipper foot.

Juki DNU-1541 Single Needle Walking Foot Lockstitch Industrial Machine

Industrial walking foot machine, 2500 SPM, 9mm stitch length, 16mm presser foot lift, compound feed, for heavy leather. Durable, powerful 550W motor.

Consew 206RB-5 Walking Foot Upholstery Machine

Industrial walking foot machine, 3300 SPM, 10mm stitch length, 14mm presser foot lift, compound feed, for heavy materials like leather and upholstery. Large bobbin, reverse stitch.

Oiveinya Leather Pro

Heavy-duty straight stitch machine, iron build, 0.5cm max stitch length. Manual oiling, replaceable foot. Strong for repairs & thick materials. Fuel powered.

LIKARVA Leather Champ

3000 SPM lockstitch machine for thick materials. 7mm max stitch, auto-lube, DP*5 needles. For jeans, tents, leather. Heavy duty, stable.

COMPREHENSIVE GUIDE TO CHOOSING THE RIGHT SEWING MACHINE FOR LEATHER

There is a plenty of factors to consider, when selecting a sewing machine for leather, like power, durability, and specific features designed to handle thick materials. This detailed buying guide will help you to choose the right one:

Key features to look for when choosing the right sewing machine for leather:

1. Powerful Motor

Leather is tougher than regular materials, and it needs a strong motor to handle those thick layers. And high-power motor is what you need, because it guarantees seamless sewing through dense materials.

2. Heavy-Duty Needles

Specialized leather needles are resistant to breaking and can endure the strain. To prevent breakage, leather needs specific leather needles, which are thicker and have a rounded point. Check to see if the machine can accommodate leather needles, which are typically 100/16 or 110/18 size.

3. Adjustable Stitch Length and Width

Consider a sewing machine with customizable straight stitch and adjustable stitch length. Leather may be thick, so a longer stitch helps to avoid excessive perforation. In addition, this flexibility allows you to customize your stitches for different leather thicknesses.

4. Strong Feed Dogs

Strong feed dogs ensure smooth fabric feeding, which is crucial for thick, stiff leather. Additionally, check for a dual-feed system or multiple feed dogs, that are preferable for leather since they assist pull the leather through the machine evenly.

5. Robust Construction

A metal frame and sturdy structure provides long-lasting performance and helps when handling heavy-duty tasks. Look for machines made of all-metal parts or cast iron to withstand the pressure of stitching through thick leather layers.

6. Walking Foot

A walking foot is particularly helpful for thick fabrics like leather because it helps feed the cloth evenly. It prevents shifting and bunching by feeding the leather evenly from both the top and bottom. Some machines come with a walking foot or allow you to purchase one separately.

7. Reverse Stitch Button

A reverse function helps to prevent unraveling by locking your stitches at the beginning and end of a seam. It is particularly helpful for securing the stitching ends when handling leather.

8. Adjustable Presser Foot Pressure

The degree of how tightly the foot presses the leather while moving is controlled by the presser foot pressure. You may fine-tune for varying leather thicknesses using a machine that has adjustable presser foot pressure since leather requires less pressure than lightweight materials.

9. High-Speed Sewing & Speed Control

A variable speed servo motor gives more flexibility and provides precise control when working with delicate materials or intricate regions, because leather may be challenging to deal with at high speeds.

ADDITIONAL FACTORS TO CONSIDER WHEN CHOOSING A LEATHER SEWING MACHINE:

Maximum Sewing Thickness & Machine Versatility

Make sure the machine is able to handle the thickness of the leather you will work with. Think about the particular needs of your projects; will they be like heavy-duty saddles or lightweight wallets, as an example?

Therefore, the type of machine you need, depends on the kind of leather you’re going to deal with.

Select a machine that can handle leather and other thick or special fabrics if you want it to be versatile and plan to use it for a variety of materials (like an upholstery fabric, canvas, or denim).

Portable vs. Stationary

Think about what you actually need, that is very important – a portable machine or a staionary machine. Portability may be important if you need to transport your machine for workshops or projects or if you move your workspace regularly. However, stationary machines are typically more reliable and preferable for professional usage.

TYPES OF FEED MECHANISM

| Compound Feed / Compound Walking Foot | Drop Feed / Regular Feed | Needle Feed | |

| How it works | The presser foot and feed dogs move in unison to advance the material evenly. The presser foot applies downward pressure, while the feed dogs grip and move the material forward. This synchronized action is crucial for sewing thick, slippery materials like leather. | The feed dogs move the material forward, while the presser foot applies downward pressure. | The needle itself contributes to the feeding process, pushing the material forward with each stitch. |

| Benefits | Prevents material shifting, ensures even fabric feed, ideal for thick and bulky materials. | Simpler mechanism, suitable for lighter fabrics and basic sewing tasks. | Useful for delicate fabrics and materials that require precise feeding. |

| Limitations | Can be less effective with thick, slippery materials like leather, as the material may shift or pucker. | May not be as effective for thick, heavy materials like leather. |

Compound feed mechanisms are typically preferred for leather stitching since they can handle thick, stiff fabrics and don’t shift. They provide a smoother, more reliable stitching experience and give you better control.

BEST TIPS FOR SEWING LEATHER AT HOME

1. Prepare Your Leather

Make sure the leather is dry, clean, and clear of any dirt or debris before starting to stitch. In addition to making the leather simpler to work with, it can help soften the leather and reduce the possibility that it will break or crack while sewing.

2. Mark Your Pattern

Mark your pattern pieces on the leather with fabric chalk, an awl, or a leather punch. Pins can cause permanent holes in the cloth, so avoid using them. A rotary cutter is very useful for accurate cutting of leather parts.

3. Use a Longer Stitch Length

When stitching leather, a longer thread length is better to use since shorter stitches may cause the fabric to tear. Longer stitches provide greater strength and help to prevent perforation, keeping the leather intact over time.

4. Adjust Your Machine Tension

Make sure the tension on your sewing machine is set correctly. While too loose tension might result in sloppy or uneven stitches, too tight strain can cause the thread to break.

5. Use a Walking Foot

In order to keep the leather from shifting or bunching, a walking foot helps feed it through the sewing machine evenly. This is particularly helpful for thicker leather sewing projects.

6. Hand-Stitching

Think about using hand-stitching methods like the saddle stitch for a more traditional and durable finish. Although it may take longer, hand stitching provides an elegant and handcrafted look, that is both durable and unique.

7. Edge Finishing

Because leather edges are prone to fraying, thorough finishing is essential. In addition to enhancing the look of your leather, techniques like edge painting and burnishing also prevent it from wear and tear over time.

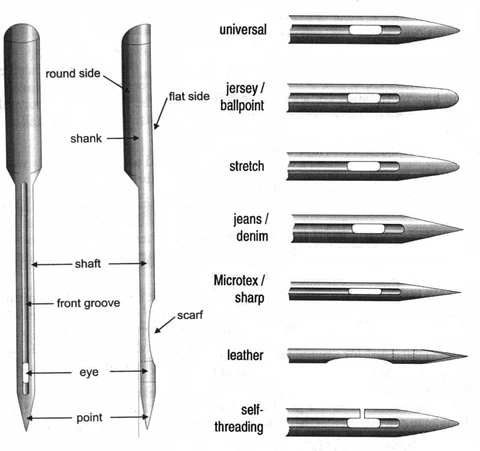

TYPES OF NEEDLES FOR LEATHER SEWING MACHINES

There are several types of needles commonly used in leather sewing machines, each type of needle is made to work with particular leather thicknesses and stitching processes:

1. Leather Needles:

The sharp triangular point of these needles easily pierces leather. They work well with a wide range of leather thicknesses.

Also a rounded tip of these needles lets it to slide smoothly over ther leather’s surface, reducing friction and the risk of punctures. That makes them ideal for delicate leathers or other materials.

2. Jeans Needles:

These ones are generally made for denim, jeans needles but may also be used for various leathers, particularly lighter-weight ones. They can pierce leather without breaking because to their strong, sharp point.

3. Wing Needles:

Its slightly curved point, helps to reduce friction and prevents the needle from breaking. They are commonly used for sewing thicker leathers.

WHAT SIZE NEEDLE DO YOU USE TO SEW THROUGH LEATHER?

- Size 14: Good for medium-weight leathers.

- Size 16: Better use for thicker leathers.

- Size 18: Ideal for leather that is very thick or has several layers of leather.

To penetrate the thick material, you will often need to use a heavy-duty needle with a larger size .

However, the needle size you need for stitching leather depends on the thickness of the leather and the kind of thread you’re using.

Remember:

- Always select a needle size that is just a bit less than the thread’s diameter.

- To achieve neat stitches and prevent breakage, use a high-quality, sharp needle.

- For easier feeding, especially with synthetic leathers, think about using a ballpoint needle.

APPLICATIONS

A leather sewing machine’s power, feed system, and needle size determine its specific capabilities. However, the majority of machines are used in a wide range of materials, crafts, and applications since they can handle a large number of materials in addition to leather.

Leather Goods:

- Bags and purses

- Wallets and belts

- Jackets and coats

- Shoes and boots

- Luggage and backpacks

Automotive Upholstery:

- Car seats

- Dashboards

- Door panels

Furniture Upholstery:

- Sofas

- Chairs

- Ottomans

Saddlery:

- Saddles

- Bridles

- Halters

Clothing:

- Leather jackets

- Leather pants

- Leather accessories